Packaging

We have partnered with KW PACKAGING to provide you with solutions for your bread slicing and bagging requirements.

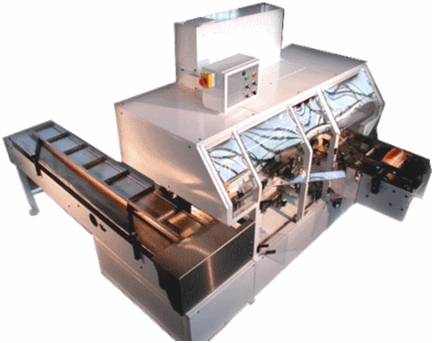

SLICERS

High speed bread slicing

FEATURES:

Stainless Steel main outer cladding

A high speed machine capable of operating at 70 loaves per minute, depending on the product

Able to be fully synchronized with the operation of a bagging machine

P.L.C electronic controls

Frequency inverter variable speed drive

Soft start, soft stop features reduce machine wear

Precision engineering design means reduced maintenance and less wear

Through the frames side belts for optimum product handling and consistent slice thickness

Pneumatic retraction system designed to speed up slicing frame changeover

Designed for low maintenance with the Maintenance Manager in mind

Speed ramp-up and slow-down capabilities for in-line mass production

Dynamically balanced crankshaft

Slicing blade angle set for optimum slicing efficiency

PRODUCT DIMENSIONS:

Length: 130 to 356mm

Height: 75 to 170mm

“Machine weight: 810kg

Bagging Machines

Eurotech 20

• A high productivity-packaging machine designed specifically for smaller bakeries

• Two operators can slice, bag and close the bags of 1,000 loaves per hour

• Designed and manufactured in South Africa

• Soft start, soft stop features means reduced maintenance and less wear

• No compressed air required

• Normal 220-volt electricity supply

• Low maintenance, easy to operate

• Ideal for stop start batch production environments

• Reusable plastic bag clips for bag closure respond to the consumer`s requirements

• Choice of left or right hand layout

• Simple to install and commission, Can be shipped in one piece

• Designed to accept low cost industrial disposable slicer blades. No skill blade changes

General Information:

PRODUCTION SIZE:

• Length : 140 to 300mm

• Width : 80 to 140mm

• Height : 80 to 155mm

BAG MATERIAL:

• Low density, high slip 25 micron or more polythene bags.

• Other materials can be used

POWER: 220V 1 phase 15 amp

WEIGHT: 710Kg

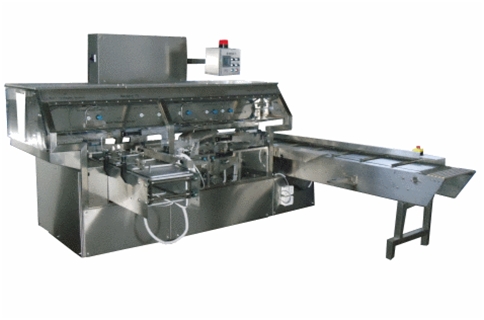

Eurotech 40

• A Med-speed bagging machine designed to cruse at 40 packs per min (2400 p/h)

• A Med-speed bagging machine designed to cruse at 40 packs per min (2400 p/h)

• Three-paddle design means slow moving parts whilst operating at cursing speed

• P.L.C electronic controls

• Frequency inverter variable speed drive programmed for three speeds

• Soft start, soft stop function to reduce maintenance and wear

• No product no load function

• Designed for low maintenance with the maintenance manager in mind

• Operator controlled console on swinging arm to allow operator flexibility

• Full synchronization facility for connection to high-speed bread slicer

• Speed ramp-up and slow-down capabilities for in-line mass production

• Automatic slow down to idle speed when no product available

• Various layout configurations

• Machine stop and warn when last bag in the wicket is used

• Overhead pusher conveyor clutch protection

• Flighted synchronizer for handling sliced bread automatically

• Accepts any conventional type of bag closure systems.

• Incorporates overhead product protection clutch

• Automatic transmission chain tensionlers throughout

• Optional Self-diagnostic LED fault indicator screen

PRODUCTION SIZE:

• Length : 140 to 300 mm

• Width : 80 to 140 mm

• Height : 80 to 155 mm

BAG MATERIAL:

• Low density, high slip 30 micron or more polythene bags

• Other materials can be used

•

POWER:

• 380V 3 phase, 50Hz

• 0.37 KW connected load 2 amp

• Compressed air (clean & dry) at 6-bar. Min ½ “BSP pipe connection.

• Air consumption 12 to 18 cubic feet per min. (0.4 to 0.6 cm/m)

Eurotech 70

Five-paddle design means slow moving parts whilst operating at high-speed

Five-paddle design means slow moving parts whilst operating at high-speed

• P.L.C. electronic controls

• Frequency inverter variable speed drive programmed for three speeds

• Soft start, soft stop features reduce machine wear

• Precision engineering design means reduced maintenance and less wear

• Self-diagnostic LED fault indicator screen

• No product, no load features

• Designed for low maintenance with the Maintenance Manager in mind.

• Operator control console on swinging arm to allow operator flexibility

• Full synchronization facility for connection to high-speed bread slicer

• Speed ramp-up and slow-down capabilities for in-line mass production

• Automatic slow down to idle speed when no product available

• Various layout configurations

• Machine stops and warns when the last bag in the wicket is used

• Overhead pusher conveyor clutch protection

• Flighted synchronizer for handling sliced bread automatically

• Optional automatic wicket changing mechanism

• Accepts any conventional type of bag closure systems

• Incorporates overhead product protection clutch

• Door safety interlocks

• Double loaf detector stops the machine automatically

• Automatic transmission chain tensioners throughout

PRODUCTION SIZE:

• Length : 140 to 300mm

• Width : 80 to 160mm

• Height : 80 to 155mm

BAG MATERIAL:

• Low density, high slip 30 micron or more polythene bags

• Other materials can be used

POWER:

• 380V 3 phase, 50Hz

• 0.37 KW connected load 2 amp Connection

• Compressed air (clean & dry) at 6-bar. Min ½ “BSP pipe

• Air consumption 12 to 18 cubic feet per min. (0.4 to 0.6 cm/m)

Afrilock Bag Closure System

• Operates at speed up to 70 closures per minute

• Operates at speed up to 70 closures per minute

• Fits all makes of bagging machines

• Accommodates all makes of plastic clips

• Fully automatic

• Clip holder takes rolls of 5000 clips

• Optional extra: Eurolock Brush Tensioner Unit

• Can be supplied as a stand-alone unit for varied bag closure applications

PRODUCTION SIZE:

• Length : 250mm

• Height : 1140mm (370mm shipping)

• Width : 300mm

• Weight : 22.1Kg

POWER:

• 220V, inverted drive

• 0.21 Kw

• Air: 5 bar pressure

• 180Cu cm/hr